For distributors of industrial gases and hardgoods, distribution as a percent of operating costs is significant. In fact, according to John Campbell of Intelligas Consulting, cylinder delivery is the most important cost in a typical distributor’s operations and often the least understood and managed. Today, the availability of GPS, asset tracking tools, and increasingly sophisticated software enables distributors to capture the data needed to understand and manage their distribution costs in a way not possible even five years ago. As David Schaer, President of Computers Unlimited (CU) states, "Technology is now at hand that allows industrial gas distributors to implement Uber-like capabilities to improve delivery operation efficiencies."

A case in point

This year [2019] Computers Unlimited introduced its new TIMS Delivery application – but not before it did its homework. A CU customer with a large fleet of over 150 delivery trucks across 22 branch locations, needed a solution that both made delivery operations run smoother and more efficiently. With oxygen cylinder orders representing over 30% of this customers 2,800 daily deliveries, finding a way to curb escalating delivery costs, without impacting the client’s commitment to courteous service and unparalleled support, was a tall order.

The company’s delivery challenges included many that are familiar to independent gas distributors: improperly routed trucks; inefficient use of fuel and driver time; a need to accommodate last-minute orders; and the failure of existing processes to correctly input hand-written and paper orders. Factors like this added costs to the company by creating higher rates of overtime pay, fuel use, and the duplication of orders. To improve its bottom line, the customer listed the following objectives for its new software program: (1) delivery routing capabilities with turn-by-turn directions to save on the cost of fuel and maintenance; (2) a system that would reduce paperwork; (3) a program that connected inventory, loading, delivery, and payment into one integrated system.

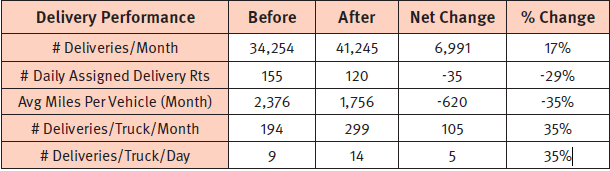

With TIMS Delivery, the client was able to hit all three marks. As shown in Figure 1, the company was able to achieve much better delivery performance, reducing deliveries per month by 17%, trimming daily assigned delivery routes by 29%, and reducing average miles per vehicle (per month) by 35%. This enabled the company to utilize its fleet much more efficiently, making 299 deliveries per truck per month, as compared to 194, a 35% increase. It achieved the same rate of increase for daily truck deliveries. The new routing software also enabled this distributor to create more efficient routes, add orders on the fly, and take on-site payments. For its cylinder deliveries, which can be up to twenty-five in one stop, the company attained a “drop and go” rate of 2.5 minutes from arrival to departure.

By replacing its outdated technologies and manual procedures with its new software package, the company reports it has achieved fuel savings of 39%. It also reduced dispatching labor cost by 65%, driver costs by 22%, and back-office labor costs by an amazing 86%. The total actual savings gained by implementing this fleet management system was over $4.5m in the first year.

TIMS Delivery Case Study

TIMS Delivery Case Study

Source: Computers Unlimited

Efficiency without sacrificing service

With savings numbers like that, it is easy to see how software is revolutionizing the business of moving products. From an operations standpoint, fleet management systems enable the kind of clear measurement of the cost of goods and inventory that reduces error rates and improves delivery measures, all of which impact your bottom line in a very positive manner. But as an industry that relies on the excellence of its customer service as its primary competitive advantage, can these systems make you more efficient without negatively impacting that critical element? CU’s client gives its fleet management system an emphatic “thumbs up” from a service perspective. It found the software enabled them to better track inventory, trucks, drivers, and delivery and payment status, all of which improved their customer service capabilities.

This article originally appeared in gasworld U.S. magazine in February 2019 and was written by Agnes Baker, a regular contributor to gasworld U.S. on all matters of industrial and specialty gases.

Ready to talk?

Last updated: February 1, 2024